Sustainability in Action: Mushrooms Replace Polystyrene Packaging

By The Editors

We’re all familiar with polystyrene, one of the most widely used plastics. Because polystyrene can be easily cast into molds with fine detail, it has a zillion uses and you can find it everywhere. Think of protective packaging products such as packing peanuts (foam peanuts), clamshell containers, CD and DVD cases, lids, bottles, trays and more.

Polystyrene is very slow to degrade – it persists in the environment for a long time. Do you remember the Great Pacific Garbage Patch and the Plastic Footprint? What can be done to address this global environmental issue? Here we have an example: an innovative idea that becomes mushroom-based packaging, and ….. it’s not just recyclable — it’s compostable!

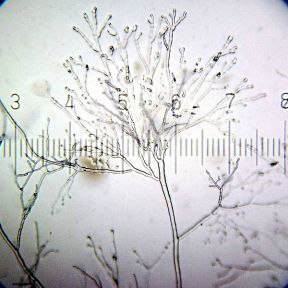

When you see a mushroom, you see the fruiting body of the fungus — the mushroom is actually only a small, visible part of a much larger fungus. The main part of the fungus is underground in the form of mycelium. The mycelium has been described as Earth’s natural Internet and is composed of thread-like filaments called hyphae, which secrete enzymes necessary for breaking down sources of nutrients. The size of a mycelium varies — it can be so minute the naked eye can’t see it or as large as an acre or more.

A few years ago, Eben Bayer and Gavin McIntyre, at the time students at the Rensselaer Polytechnic Institute, thought of using mycelium as a resin. Their idea led them to found a company, Ecovative. Ecovative’s products can replace materials ranging from petroleum based expanded plastics (like Styrofoam™) to particle board made using carcinogenic formaldehyde.

Ecovative’s raw materials come from farms and consist of parts of plants that cannot be used for food or feed. These agricultural materials are blended, cleaned and inoculated with mycelium. After inoculation, the mixture is filled evenly into forms in an automated process. The mycelium grows indoors in about a week without any need for light, watering or petrochemical inputs, and in any needed shape. When the growth necessary to obtain the desired shape is complete, the materials are dehydrated and heated so there will never be any spores or allergen concerns.

This is a clear example of sustainable products. A few days ago, we discussed greenwashing. Here, we have the opposite situation – a truly green company that produces natural, renewable and biodegradable products with the potential to effectively decrease the plastic footprint.

One Comment

Nisha Hudda

This is an innovative thought and invention. I would have never thought that something we consume such as mushrooms can replace the foam peanuts. I believe it is an amazing thing that great minds are coming together to make our environment an eco friendly environment. There are great companies such as Ecovative that make inventions such as this but also take in ideas from others and incorporate that in their products. I also respect the fact that the company took concern of the allergy issues of the public and heated the spores of the mushroom so it will not affect the individuals who are allergic to mushrooms. After doing some research I discovered that Ecovative has received four of the highest ranking awards for their packaging design with the mushroom and agricultural crop waste combined. http://www.mushroompackaging.com/

I believe that this invention highly deserves these type of awards to not only reward them but also to encourage others to strive to come up with these eco friendly ideas to make this world a better place to live.